Causes of Vibration Motor Burnout and Preventive Measures

In the process of using the vibrating screen, the vibration of the vibration motor is also a relatively common failure. So what causes such failures? The following is a detailed description of the causes and preventive measures of several types of vibration motors:

1) Loosening of anchor bolts

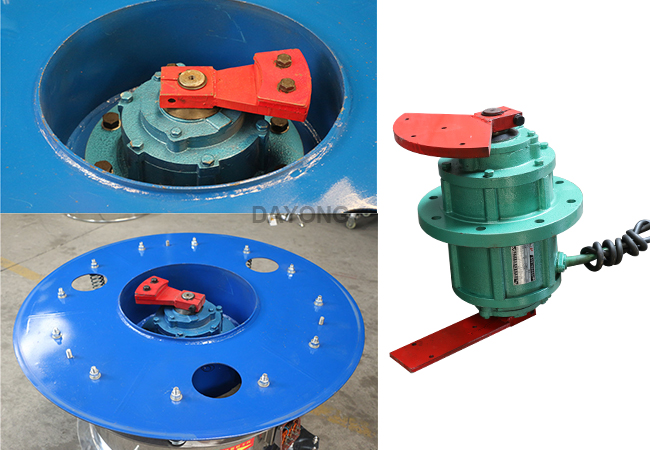

This is one of the main failures that cause the vibration motor to burn out. Due to the special structure of the vibration motor itself, the excitation force generated by the eccentric blocks at both ends must impact the anchor bolts 2,000 times per minute. Participate in vibration, so the anchor bolts are very easy to loosen. Once a bolt is loosened, it will cause other bolts to loosen or even break in a short time, which will burn the motor.

Preventive measures: ① often reinforce the anchor bolts; ② increase the anti-loosing device; ③ ensure that the foot surface and the motor floor are in good contact, so that several anchor bolts are uniformly stressed.

In the selection of materials, try to use a vibration motor with an integrated shell seat (that is, the foot surface is on the chassis), because the foot surface is processed at one time, it can ensure its level. The shell seat is different (that is, the foot surface is on the two end covers), because the foot surface is processed in stages and reassembled. Due to the existence of assembly errors, it is difficult to ensure the level of the foot surface. The force is not easy to be uniform, and a bolt with a large force will easily loosen, which will cause other bolts to loosen and break, and burn the motor.

2) Installation issues

Because both ends of the vibration motor are equipped with heavy eccentric blocks, such as vertical or oblique installation (that is, the rotating shaft is vertical or inclined horizontal plane), the bearing axial direction must bear the gravity of the eccentric block. If there is no special device in the vibration motor, it will adversely affect the bearing and shorten the service life.

Preventive measures: ① choose vertical vibration motor (that is, increase the plane bearing inside); ② try to avoid vertical or inclined installation.

3) Adjustment of eccentric block

When adjusting the eccentric block, the direction of the eccentric blocks at both ends is mistakenly reversed, so that the vibration motor generates a space torque, which causes the vibration motor to work in an abnormal state, thereby causing burnout. Therefore, when adjusting the eccentric block, we must pay attention to its symmetry, that is, the eccentric blocks at both ends must correspond to each other, or the center of gravity connecting line of the eccentric blocks at both ends must be parallel to the axis of rotation, and cannot be in a different plane state.

4) Sealing problem of protective cover

Because the working environment of vibration motors is very harsh and dust is large, if the protective cover is not tightly sealed, it is easy to enter the dust and cause the frictional operation of the eccentric block, thereby burning the motor. Therefore, in places where the working environment is harsh, one is to increase the sealing of the protective cover, and the other is to clean the dust inside the protective cover frequently.

5) Ambient temperature

The material temperature of the equipment cannot be too high. Because the vibration motor and the device are rigidly connected, it can be said as a whole. If the temperature of the material conveyed by the device is too high, it is easy to cause the temperature of the floor and the casing of the vibration motor to increase, which will cause heat dissipation difficulties and burn the motor.

Preventive measures: ① Keep the vibration motor away from high-temperature materials as far as possible without affecting the work of the equipment; ② Find ways to reduce the temperature of the materials.

6) Thermal issues

Ordinary motor-there is a fan at the end, which allows the wind to flow along the vertical ribs on the chassis during operation, which not only dissipates heat quickly, but also removes the dust on it, so that the motor works in a good state. Vibration motors can dissipate heat due to no fans, and all rely on natural cooling. In addition, the working environment is very harsh, dust is large, and dust is easily accumulated on the surface of the motor, which causes the internal temperature to be too high and burns the motor.

Preventive measures: ① often remove the dust on the surface of the motor to make it work in good conditions; ② During the design process, the surface of the vibration motor should be as smooth as possible to prevent dust from accumulating. If working in a dusty environment, consider reducing Remove the heat dissipation ribs on the surface of the cabinet, because at this time, the heat dissipation ribs not only do not play a role in heat dissipation, but also easily cause dust to accumulate and hinder the heat dissipation of the motor.

(Live chat)

(Live chat)

_213x160.jpg)

+86-15136770681

+86-15136770681 sale@vibratingscreen.cc

sale@vibratingscreen.cc +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position: