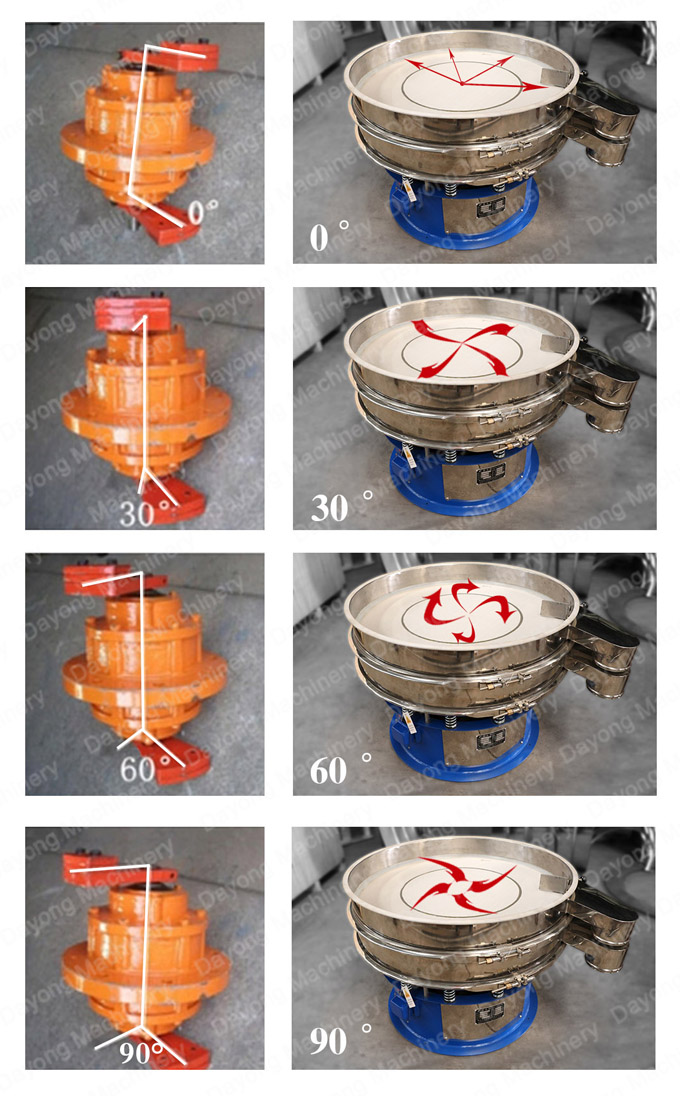

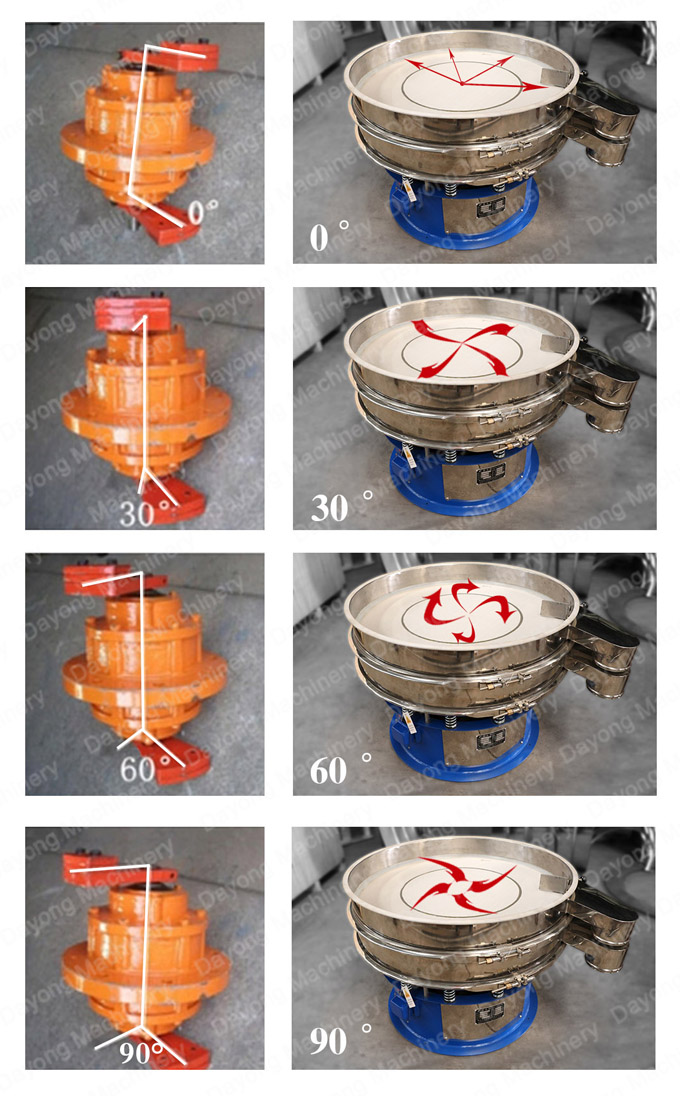

How to adjust the vibration motor angle?

According to the different materials, the proportion of the material, the different mesh size of the materials, the motor angle is needed to change.

Change the angle of the upper and down heavy hammer on the motor, then it will adjust the surface moving trajectory of the materials on the sieve , so as to achieve the better Screening effect.

For the larger size materials, usually the angle range of five to fifteen degrees is good, so that the material can be quickly moving to the edge, then the production capacity is bigger.

some material mesh is relatively small, for example, 40 to 80 mesh zise, in order to achieve the better screening effect, then we should extend the material in the screen surface, usually need adjust angle generally between 30 and 45 degree, if the material mesh size is finer than 80 mesh, then we usually need adjust angle generally between 65 and 85 degree.

About the angle of the motor adjustment, please as belows;

when we face our vibration motor, the upper heavy hammer is in your left hand direction, the down heavy hammer is in the direction of your right hand, two heavy hammer at the face of your body, that is what we say angle.

(Live chat)

(Live chat)

_213x160.jpg)

+86-15136770681

+86-15136770681 sale@vibratingscreen.cc

sale@vibratingscreen.cc +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position: