-

How to choose the bouncing ball?

How to choose the bouncing ball?

The bouncing ball, also known as the elastic ball, is an indispensable small part of the rotary vibrating screen. Its function is to imitate the manual beating of the screen surface by circulating in the middle of the rotary vibrating screen screen and the support plate, so that the material attached to the screen surface is removed from the screen and the screening output and accuracy are avoided.

-

What methods are used to reduce the paste rate on the trommel screen surface?

What methods are used to reduce the paste rate on the trommel screen surface?

There are certain differences between the drum screen and the vibrating screen. It has a large screening capacity and a large contact area with the materials. However, during the screening process, some materials that are easy to stick to the mesh will increase the mesh coverage rate of the screen surface. Let's take a look at some methods. It can reduce the paste rate of the screen surface.

-

What are the advantages of liquid sieves?

What are the advantages of liquid sieves?

Liquid sieves are widely used. Why is it so popular? Xinxiang Dayong Machinery will provide you with a detailed introduction to its advantages.

-

.jpg) How to improve the screening efficiency of ultrasonic vibrating screen?

How to improve the screening efficiency of ultrasonic vibrating screen?

The factors that usually affect the screening efficiency of ultrasonic vibrating screens include screen mesh, vibration motor, and material properties. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction.

-

.jpg) Can screw conveyors adjust conveying height?

Can screw conveyors adjust conveying height?

screw conveyors can usually achieve different conveying heights by adjusting their design and settings. This flexibility makes screw conveyors an effective conveying device suitable for a variety of production scenarios.

-

What are the advantages of a linear vibrating screen?

What are the advantages of a linear vibrating screen?

Linear vibrating screen is a relatively large screening equipment. Large processing capacity and high screening accuracy. Xinxiang Dayong Machinery will introduce its advantages in detail to you.

-

What are the advantages of ultrasonic vibrating screen?

What are the advantages of ultrasonic vibrating screen?

Ultrasonic vibrating screen solves the problem of difficult screening caused by static electricity and clumping of materials. Xinxiang Dayong Machinery will introduce its advantages in detail to you.

-

What are the advantages of a screw conveyor?

What are the advantages of a screw conveyor?

Spiral conveyors are widely used. Why is it so popular? Xinxiang Dayong Machinery will provide you with a detailed introduction to its advantages.

-

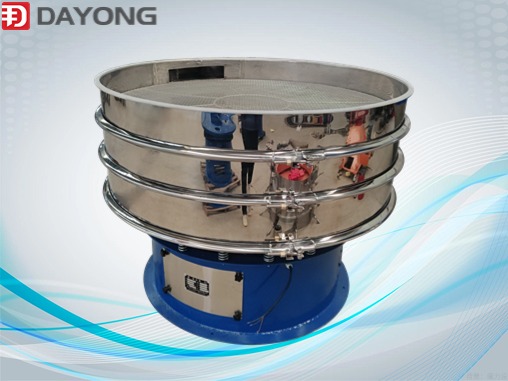

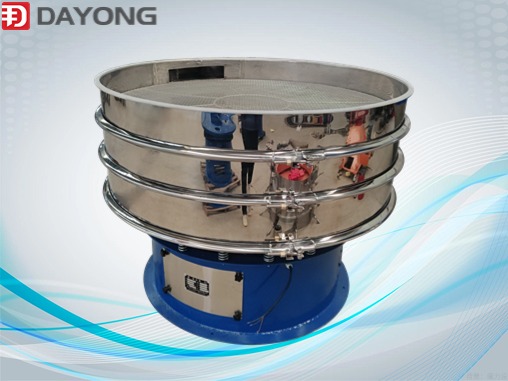

How to improve the screening efficiency of the rotary vibrating sieve?

How to improve the screening efficiency of the rotary vibrating sieve?

The factors that usually affect the screening efficiency of a rotary vibrating screen include: model, screen mesh, vibration motor etc. Xinxiang Dayong Vibration Equipment Co., Ltd. will provide you with a detailed introduction.

-

.jpg) What materials are suitable for screening with a circular swing screen and its advantages?

What materials are suitable for screening with a circular swing screen and its advantages?

Circular swing screen can easily complete large-scale, high-density screening tasks.Xinxiang Dayong Machinery will introduce to you which materials are suitable for round swing screens and the advantages of screening.

-

.jpg) Reasons for frequent tripping of vibration motors

Reasons for frequent tripping of vibration motors

Reasons for frequent tripping of vibration motors

-

.jpg) When choosing a suitable rotary vibrating screen, you need to consider the following factor

When choosing a suitable rotary vibrating screen, you need to consider the following factor

When choosing a suitable rotary vibrating screen, you need to consider the following factor

-

Which conveyor should be used for aggregate transportation?

Which conveyor should be used for aggregate transportation?

Several factors should be considered when selecting the type of aggregate conveyor, including the following key factors:

-

How much output can the U-shaped screw conveyor achieve?

How much output can the U-shaped screw conveyor achieve?

The output of U-shaped screw conveyor will be affected by many factors, including but not limited to the following aspects:

-

How much output can the U-shaped screw conveyor achieve?

How much output can the U-shaped screw conveyor achieve?

The output of U-shaped screw conveyor will be affected by many factors, including but not limited to the following aspects:

-

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

What aspects should be paid attention to when cleaning and maintaining screw conveyors?

-

.jpg) How to screen slurry?

How to screen slurry?

How to screen slurry?

-

.jpg) Structural of screw conveyor

Structural of screw conveyor

Structural of screw conveyor

-

.jpg) Analysis of the causes of clogging of the rotary vibrating screen

Analysis of the causes of clogging of the rotary vibrating screen

Analysis of the causes of clogging of the rotary vibrating screen

-

.jpg) What general failures will occur in the rotary vibrating screen

What general failures will occur in the rotary vibrating screen

What general failures will occur in the rotary vibrating screen

-

.jpg) Is it necessary to polish the stainless steel vibrating screen?

Is it necessary to polish the stainless steel vibrating screen?

High quality screening and conveying machinery supplier! Xinxiang Dayong Vibration Equipment Co., Ltd., we produce high-efficiency rotary vibrating sieves, linear vibrating sieves, liquid sieving filters, circular swinging sieves. We produce screw conveyors, belt conveyors, vacuum feeders, bucket elevators, etc. We can provide screening conveyor machinery production lines.

-

What other factors need to be considered when choosing a coal conveyor?

What other factors need to be considered when choosing a coal conveyor?

When selecting a conveyor, in addition to the nature of the coal and conveying requirements, the following factors need to be considered

-

What conveyor should be used for coal transportation?

What conveyor should be used for coal transportation?

Choosing a conveyor suitable for coal transportation requires consideration of many factors, including the nature of the coal, transportation distance, transportation volume, working environment and cost. Here are a few common conveyor types suitable for coal transportation:

-

How to choose the mesh size of square swing screen?

How to choose the mesh size of square swing screen?

Selecting the mesh size of the square swing screen requires considering factors such as graphite particle size distribution, screening requirements, screening efficiency and application experience, and conducting actual testing and verification to obtain the best screening effect.

-

Can a square swing screen be used for graphite screening?

Can a square swing screen be used for graphite screening?

Square swing screen is a common vibrating screening equipment, suitable for screening and classifying granular materials. For screening graphite, square swing screens can operate efficiently.

(Live chat)

(Live chat)

_213x160.jpg)

+86-15136770681

+86-15136770681 sale@vibratingscreen.cc

sale@vibratingscreen.cc +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)