-

.jpg) How does the vibrating screen work

How does the vibrating screen work

How does the vibrating screen work in vibratingscreen.cc

-

.jpg) How to improve the screening efficiency of vibrating screen

How to improve the screening efficiency of vibrating screen

How to improve the screening efficiency of vibrating screen in vibratingscreen.cc

-

What are the advantages of vehicle-mounted grain suction machine

What are the advantages of vehicle-mounted grain suction machine

What are the advantages of vehicle-mounted grain suction machine in vibratingscreen.cc

-

Advantages of linear sieve screening sewage treatment

Advantages of linear sieve screening sewage treatment

Advantages of linear sieve screening sewage treatment in vibratingscreen.cc

-

What are the advantages of scraper rotary vibrating screen?

What are the advantages of scraper rotary vibrating screen?

What are the advantages of scraper rotary vibrating screen in vibratingscreen.cc

-

.jpg) What is the problem with the straight screen not moving forward

What is the problem with the straight screen not moving forward

Xinxiang Dayong Vibration Equipment Co., Ltd. analyzes the problem of non-feeding of linear sieve for users

-

.jpg) How to reasonably select the rotary vibrating screen mesh? Control the particle size of the sieve by controlling the mesh size

How to reasonably select the rotary vibrating screen mesh? Control the particle size of the sieve by controlling the mesh size

Everyone knows that whether it is a rotary vibrating screen or a linear vibrating screen, the most important thing when screening materials is the screen mesh. The screening of materials is controlled by the mesh size on the vibrating screen, and the effective selection of the mesh is the main factor in improving the efficiency of the vibrating screen! Today, the editor will organize how to reasonably select the screen mesh for the rotary vibrating screen. I hope the majority of users can be helpful.

-

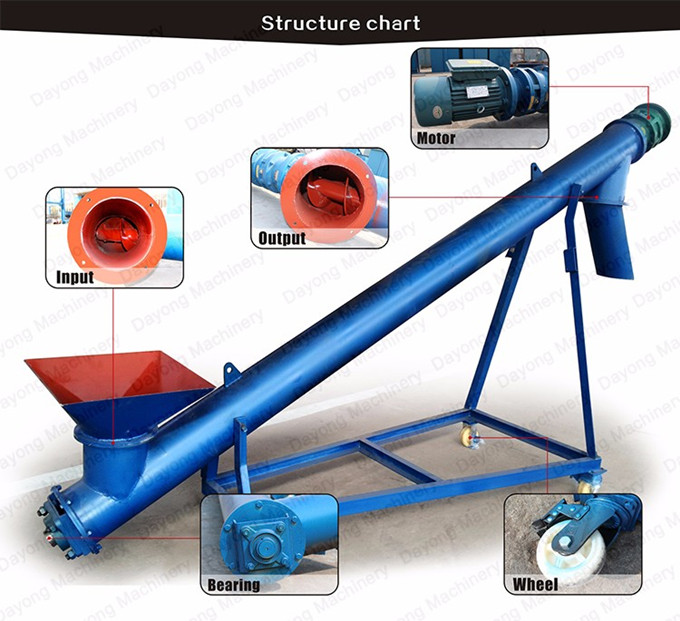

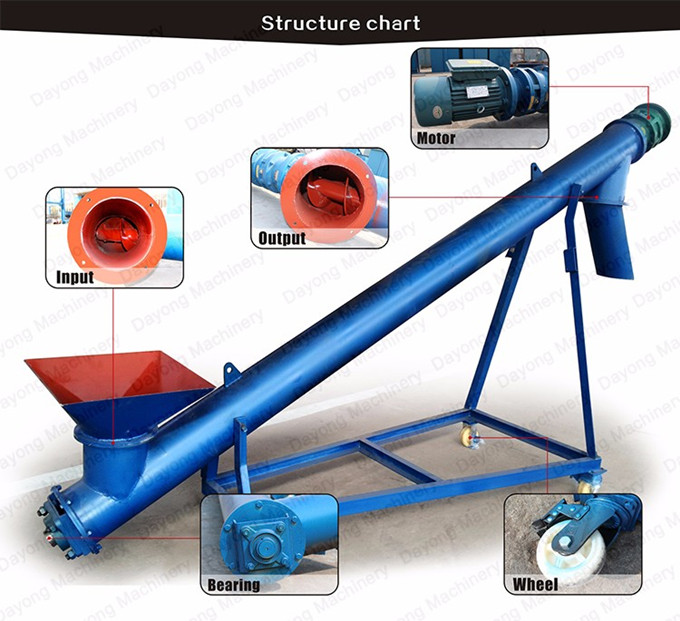

Common causes of screw conveyor failures and their corresponding solutions

Common causes of screw conveyor failures and their corresponding solutions

The screw conveyor has a simple structure, occupies a small area, is easy to seal, does not cause dust and is suitable for the transport of fine powdered and fibrous raw materials; it is not suitable for the transport of raw materials that are easily mouldy, sticky and easily agglomerated.

Screw conveyor includes drive equipment motor, reducer, raw material coal hopper, spiral shaft containing spiral leaves and support points on both sides, with inlet, pouring and checking ports underneath.

Mechanical faults include loose and broken coupling shaft ground bolts, torn spiral blades, twisted fl

-

The difference between excited high-efficiency linear vibrating screen and ordinary linear vibrating screen

The difference between excited high-efficiency linear vibrating screen and ordinary linear vibrating screen

We have all seen linear vibrating screens, but for its classification, we may say that it is divided into light linear screens and heavy linear screens. This statement is also correct, but there are still many types of heavy linear screens and light linear screens. If it is accurate, it can also be said to be divided into excitation type high efficiency vibrating screen and ordinary linear vibrating screen. So how to distinguish?

-

How can the grain suction machine be used safely

How can the grain suction machine be used safely

Grain suction machine is an automatic equipment for transporting materials, in the process of use must be familiar with the operating procedures and in accordance with the requirements to do a good job, so as to ensure the safe use of the machine, the following is the correct use of grain suction machine need to pay attention to.

-

Common problems and solutions of rotary vibrating screens

Common problems and solutions of rotary vibrating screens

Common problems and solutions of rotary vibrating screens

-

.jpg) What is the impact of loose tension on the vibrating screen frame

What is the impact of loose tension on the vibrating screen frame

The rotary vibrating screen has functions such as screening, impurity removal, and filtration. The reason why the rotary vibrating screen can efficiently classify materials is because it has a reasonable grid structure. The rotary vibrating screen mesh frame is composed of perforated plates, bouncing balls, PU rings, parent mesh, and sub mesh. This mesh structure can classify materials of different particle sizes. If the vibrating screen mesh is too loose, it will have a certain impact on screening,

-

.jpg) Analysis of the Causes of Frequent Fracture of Vibrating Screen Damping Spring

Analysis of the Causes of Frequent Fracture of Vibrating Screen Damping Spring

Damping spring, also known as damping spring, supports the screen frame and buffers the vibration force. On the other hand, it balances the screen frame and realizes the horizontal configuration of the screen frame to promote the screening accuracy and discharge volume. The frequent fracture of the vibration spring may be caused by the following problems:

-

What kind of vibrating screen is used for sieving and removing impurities with long columnar activated carbon

What kind of vibrating screen is used for sieving and removing impurities with long columnar activated carbon

Activated carbon is a columnar activated carbon made from high-quality wood chips, coconut shell, etc. through crushing, mixing, extrusion, molding, drying, carbonization, and activation. Compared with traditional coal-based columnar carbon, the ash content is lower, the impurities are less, and CTC accounts for Absolute advantage. However, some impurities may be mixed during production. Therefore, vibrating screen equipment is required to screen out the impurities in the activated carbon. Activated carbon materials come in many shapes, such as powder, granules, long bars, and irregularities.

-

How to make the grain suction machine play the most role?

How to make the grain suction machine play the most role?

Grain suction machine is a professional agricultural equipment, mainly used to suck flour or other fine grain materials. In the process of operating the grain suction machine, there are many matters that need attention, according to the requirements of the operation can mak

-

How to choose the right grain suction machine?

How to choose the right grain suction machine?

When it comes to grain transportation, everyone will definitely think of grain suction machines, which have a very wide range of application and, most importantly, are very easy to operate. Whether it is for manufacturers to carry out large quantities of grain transportation, or to say that the farmers themselves use small grain transportation, you can choose different grain suction machine.

-

How to choose a suitable linear vibrating screen?

How to choose a suitable linear vibrating screen?

In food, medicine, agriculture, chemistry, abrasives, construction, glass, plastics and other industries, users generally use screening machines. Linear screens are a type of screening machines, and the machine has a large screening output. So, how to choose a suitable linear screen for you? What about the sieve?

-

.jpg) What factors affect the working efficiency of the vibrating screen

What factors affect the working efficiency of the vibrating screen

The vibrating screen works by using the double-rotation vibration generated by the vibration of the vibrator. The upper rotating weight of the vibrator causes the screen surface to produce plane circular vibration, while the lower rotating weight causes the screen surface to produce cone surface rotary vibration, and the combined effect of the combined effect makes the screen surface produce double rotary vibration. Its vibration track is a complex space curve. The projection of the curve on the horizontal plane is a circle, while the projection on the vertical plane is an ellipse. The followi

-

What parts should be paid attention to at all times during the operation of the ultrasonic vibrating screen?

What parts should be paid attention to at all times during the operation of the ultrasonic vibrating screen?

It is increasingly important to check the condition of ultrasonic vibrating screens in operation and prepare a thorough inspection plan. Especially the ultrasonic vibrating screen bearings in important machines or harsh environments should be checked more often.

-

.jpg) How to choose a grain vibrating screen, and what are the issues that need attention?

How to choose a grain vibrating screen, and what are the issues that need attention?

Today’s industries are countless, but the food industry is something we must pay attention to. As the saying goes, illness comes from the mouth, which makes us all not pay attention to what we eat. Vibrating screens have been put into operation in various industries. However, when vibrating screen equipment is used in the food industry, we should distinguish the correct method of use. What specific matters should be paid attention to, the editor will take everyone to look down.

The correct choice of grain vibrating screen is more important, and there is no room for sloppy things. The food ind

-

.jpg) How to Solve The Problem of Slow Discharge of Rotary Vibrating Screen

How to Solve The Problem of Slow Discharge of Rotary Vibrating Screen

The solutions for solving the problem of slow discharge of rotary vibrating screen

-

Factors Affecting The Screening Efficiency of Metal Powder Ultrasonic Vibrating Screen

Factors Affecting The Screening Efficiency of Metal Powder Ultrasonic Vibrating Screen

The screen hole size and opening rate of screen surface is the main reason for the screening efficiency of ultrasonic vibrating screen.

-

What Materials Are Used For Explosion-proof Motors

What Materials Are Used For Explosion-proof Motors

There is a qualitative difference between dust explosion-proof vibration motors and gas explosion-proof vibration motors, and their requirements and standards are different.

-

What Are The Advantages of The Dust Free Feeding Station

What Are The Advantages of The Dust Free Feeding Station

Dust-free feeding station means that when the machine is working, it will not produce dust and other substances.

-

Under What Circumstances Should An Explosion-proof Vibration Motor Be Used

Under What Circumstances Should An Explosion-proof Vibration Motor Be Used

Explosion-proof electrical is an indispensable part in the production process of chemical, petroleum, electric power, metallurgy and other industries.

(Live chat)

(Live chat)

_213x160.jpg)

+86-15136770681

+86-15136770681 sale@vibratingscreen.cc

sale@vibratingscreen.cc +86-373-3669006

+86-373-3669006 From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland).

From West Room 5, 1st Floor, Building 18, Huilong Yangguang Mingyuan, New District, Xinxiang, Henan, China (Mainland). Your Position:

Your Position:.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)